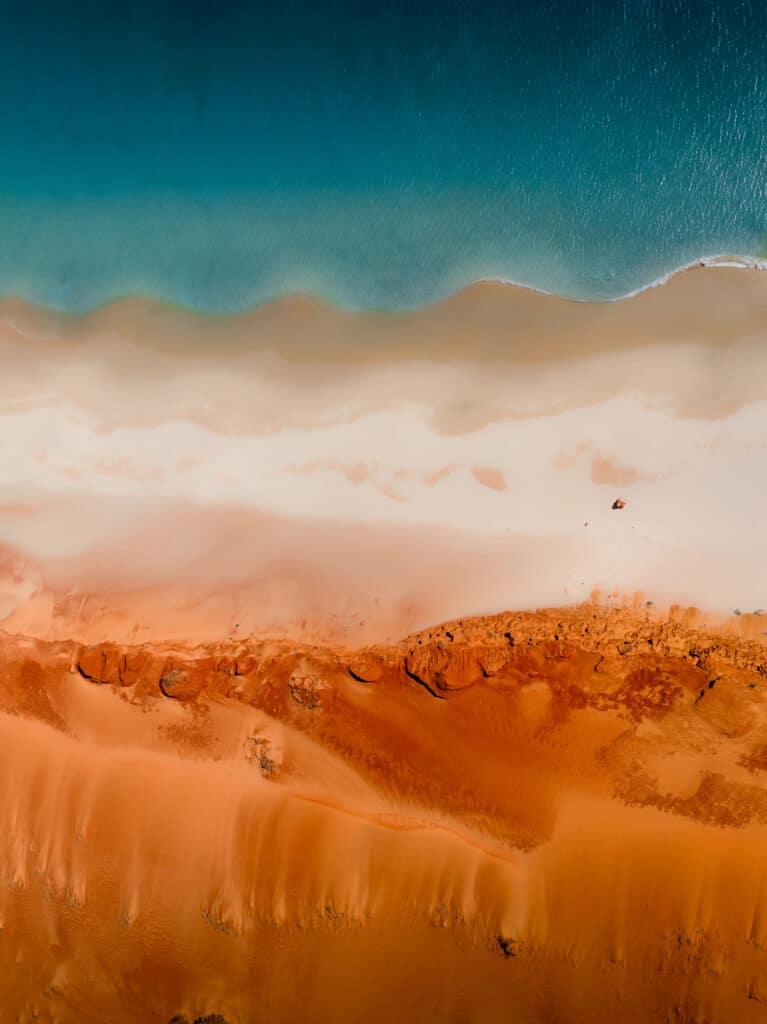

Whole-of-system mining:

a circular blueprint

In Australia, we have a habit of mining our own business!

Below ground, nature provided one valuable resource to share. Above ground, multiple companies and mine sites compete to extract that value. Where traditional mining digs for ever-deeper returns in ever-deeper siloes, a circular approach breaks down these walls and leverages collaboration to capture untapped value.

The Bowen Basin Circularity Program shifts from mining the seam, to mining the system.

Collecting the largest dataset on record for tailings & material outflows in the Bowen Basin, the flows in and out of mining, existing regional capabilities, and unrealised revenue streams. This blueprint reveals where working together unlocks undermined value.

60,000

KM² area

58

Active mines

45,000

Jobs for Queenslanders

40.1

Billioncontributed to economy

Doesn’t shared geological inheritance deserve a shared systems solution?

Surfacing value at scale

It’s about getting more from what we leave on the surface, instead of just digging deeper.

Imagine needing to move and process nearly 10 tonnes of materials just to produce 1 tonne of saleable steel-making coal. That’s the reality of coal mining today.

Materials include overburden (soil and rock), water, diesel, equipment, explosives, and more. Much of this material doesn’t disappear; it gets transformed or set aside. Because much of these materials don’t get counted as either “product” or “waste”, they disappear from sight, but stay on-site.

Multiplied across 58 active mines in Queensland, the scale of opportunity is over 150 million tonnes of materials waiting to be valorised.

A circular lens recognises that a mining process doesn’t end at the saleable tonne, it extends across every material that flows in and out of an operation.

* Input and output estimates are based on data from Queensland Government coal production figures (2024), ACARP-funded research on tailings generation (Katwal et al., 2022), strip ratio benchmarks from Queensland open-cut metallurgical coal mines, and aggregated operator-sourced mine performance data. Output figures include physical process & non-process by-products.

Learn more about our three circularity projects

This program has been delivered in partnership with the Queensland Department of Natural Resources and Mines, Manufacturing, and Regional and Rural Development (DNRMMRRD) and the Resources Centre of Excellence. These early projects are just the beginning, get in touch with Coreo to learn more and explore what’s next.

-

Full Value Realisation of Metallurgical Coal Tailings Value Proposition

LEARN MORE: Full Value Realisation of Metallurgical Coal Tailings Value Proposition -

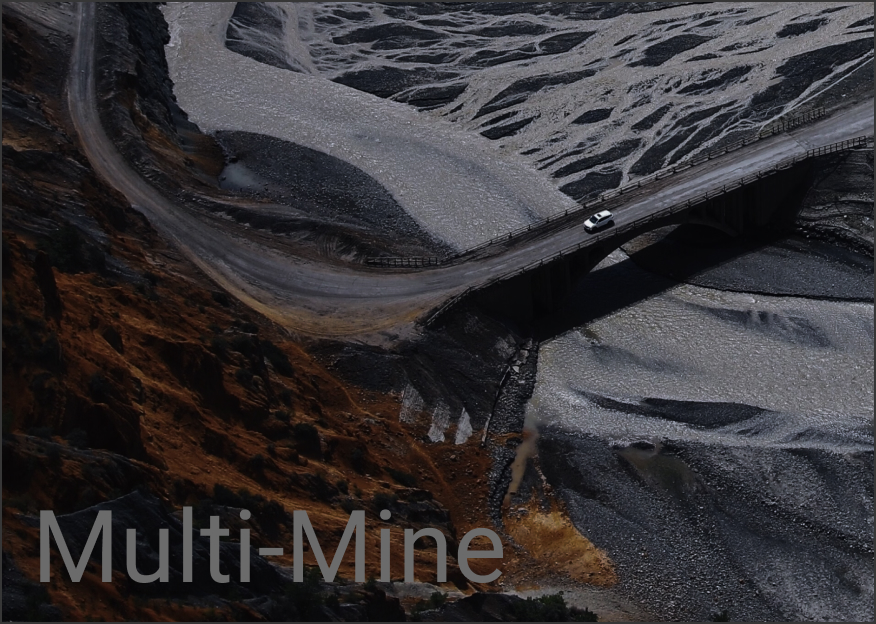

Multi-Mine Circular Resource Recovery Facility

LEARN MORE: Multi-Mine Circular Resource Recovery Facility